What to consider when laser marking metal

Both CO2 lasers and fiber lasers are very popular for marking metal with barcodes, serial numbers, and logos.

The long lifetime, low maintenance requirements, and relatively low cost of fiber lasers make them ideal for industrial marking applications. The ink produced by this type of laser is permanent and high-contrast, and it does not decay over time.

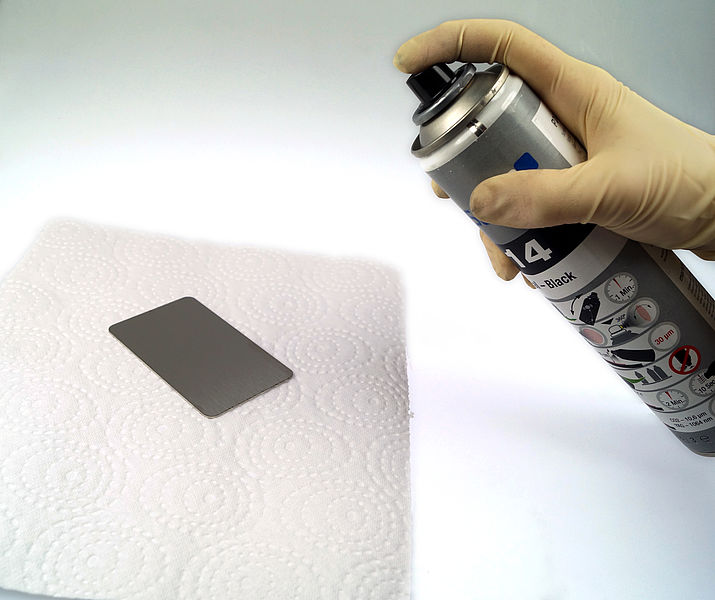

CO2 laser engraving can only be carried out on treated metals (or pastes) prior to engraving. The CO2 laser bonds metal marking agents with heat, creating permanent marks. CO2 lasers are also affordable and fast, and they can mark wood, acrylic, and natural stone.

Epilog develops laser systems that can be operated from virtually any software package on a Windows computer.

Differences between lasers

In light of the fact that different types of lasers react differently with various materials, there are some considerations to be made.

CO2 lasers take more time to mark metals, for instance, since metal marking agents must be coated or pre-treated first. Also, the marking agent needs to have high power and low speed to bond with the metal. It’s time to run the piece at a lower speed and at a higher power if the laser mark doesn’t wipe off after lasering.

Metal can be marked with CO2 lasers without removing any material from it, ensuring that its tolerance and strength are not compromised. Furthermore, painted brass and anodized aluminum do not need pre-treatment.

Laser fiber engraving is the best way to engrave metals bare. Metal and plastic fibers can be marked with laser beams including aluminum, brass, copper, nickel-plated metals, stainless steel, among others.

In some cases, however, the laser wavelength will not mark certain materials, including transparent materials; the beam, for example, can pass through transparent materials, leaving markings on the engraving table instead. Several organic materials, including wood, clear glass, and leather, can be marked using fiber laser systems, but that isn’t necessarily their best use.

Marks and their types

Based on the type of material to be marked, a variety of fiber laser marking on metal options is available. A laser is used to vaporize materials from objects through engraving. Because the beam is shaped like a cone, the mark is often shaped like that. As the system repeats the cycle, the engraving becomes deeper and won’t wear away.

Often, ablation involves removing a top layer to reveal the material underneath. Powdered and anodized metals can all be ablated.

It is also possible to mark an object’s surface by heating it. When metals are heated to high temperatures, annealing creates a layer of oxide that leaves a high-contrast mark. As the surface of a material melts, gas bubbles form which are trapped as it cools and causes a bubbled effect. During polishing, a metal surface is heated rapidly to reverse its color. A mirror-like finish is achieved as a result. In addition to steel alloys and iron, anodizing is used for titanium, titanium alloys, and other high-carbon and high-oxide metals. Plastic is usually marked with foam, but it can also be used on stainless steel. The best results tend to be obtained with darker metals with matte finishes.

Materials to Consider

By changing laser data, such as speed, power, frequency, and focus, stainless steel may also be marked using annealing, etching, and polishing procedures. A fiber laser can often produce much more brightness than a CO2 laser with anodized aluminum. When it engraves aluminum, the fiber laser produces shades of gray instead of black. Additionally, aluminum can be oxidized or colored after deep etching.

Titanium can also be marked by a laser – the laser tends to create an array of colors. By adjusting the frequency, however, different colors of marks can be produced.

Best of Both Worlds

Companies with limited budgets or space should consider dual-source systems because of their flexibility and capabilities. There is a drawback to this method, in that one side is useless when the other is in use.

Anodized aluminum with white, grey, and black marks

When aluminum is removed from its color or material, different marking effects can be achieved. The anodized layers can be completely or partially removed by laser.

A ceramic layer is formed on anodized aluminum (5-30 m thick) to protect the surface. Coloring the porous layer can produce decorative effects. The wavelength of the laser determines the kind of marking it produces (and therefore the type of material removed, as well as the layers beneath).

For instance, anodized aluminum is frequently used in machine construction. The Housings and Covers section contains screws, covers, and other parts.