What is a PCB Stencil? A Comprehensive Guide

The manufacturing industry for electronics is constantly changing, where finding a balance between efficiency and quality is crucial. A tool that has had a big impact on the soldering process during PCB assembly is the PCB stencil. This simple device has proven highly effective. pcbasic, a top supplier of PCB stencils, provides a variety of options that can help manufacturers improve their production processes. In this piece, we’ll examine the significance of these stencils, the advantages of utilizing PCB stencils from pcbasic, and how they’re changing the manufacturing world

Understanding PCB Stencils

What are PCB Stencils?

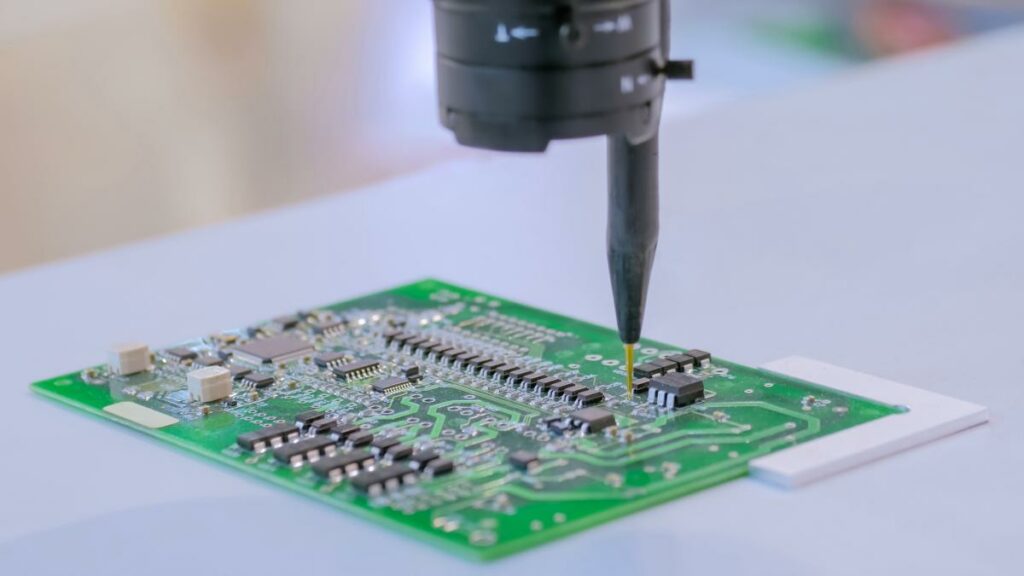

At its core, a PCB stencil is a thin sheet of material, often stainless steel, with precisely engineered apertures. These apertures align with the solder pads on a printed circuit board, facilitating the controlled application of solder paste onto the board during assembly.

The Role of PCB Stencils in SMT Assembly

Surface Mount Technology (SMT) assembly relies on precise solder paste deposition. PCB stencils act as a guide, ensuring the right amount of solder paste is placed onto the pads. This precision is crucial for preventing solder bridging and insufficient soldering – both of which can lead to faulty connections and compromised quality.

Benefits of PCB Stencils from Pcbasic

Superior Quality Stencils for Optimal Printing

Pcbasic takes quality seriously. Their stencils are manufactured using advanced techniques, resulting in clean and accurate apertures. This level of precision translates to consistent solder paste deposition and, consequently, higher product quality.

Enhanced Efficiency and Throughput

Efficiency is a cornerstone of modern manufacturing. By using PCB stencils from Pcbasic, manufacturers can streamline the solder paste application process. This leads to faster production cycles, reduced setup times, and ultimately, improved throughput.

Customization to Suit Diverse Needs

Every PCB design is unique, and Pcbasic understands that. Their stencils can be customized to align perfectly with specific design requirements. This flexibility ensures that manufacturers can tackle a wide array of projects without compromising on quality or efficiency.

Expert Guidance and Support

Pcbasic doesn’t just provide stencils; they provide expertise. Their team is well-versed in stencil design and assembly processes. This invaluable support assists manufacturers in making informed decisions, optimizing their stencil usage, and achieving exceptional results.

The PCB Stencil Revolution: Redefining Manufacturing

Precision Redefined

The precision offered by PCB stencils is a game-changer in the manufacturing world. It eradicates the inconsistencies associated with manual solder paste application, fostering a more reliable and robust assembly process.

Maximizing ROI

Investing in quality tools like PCB stencils translates to a tangible return on investment. The reduction in defects, rework, and time spent on troubleshooting elevates overall production efficiency and slashes operational costs.

Embracing Innovation

Innovation drives progress, and PCB stencils epitomize innovation in electronics manufacturing. By adopting these stencils, manufacturers embrace a technology that reflects the industry’s commitment to excellence.

Conclusion

PCB stencils stand out as a critical tool for achieving efficiency and quality in the evolving landscape of electronics manufacturing. Pcbasic’s dedication to excellence, paired with their top-tier stencils and experienced support, guarantees that manufacturers can confidently manage the intricacies of assembly. As the demand for higher-performance electronics grows, including PCB stencils into the manufacturing process is no longer an option — it’s a requirement.

FAQs about PCB Stencils and Pcbasic

- Q: What is the primary purpose of a PCB stencil? A: A PCB stencil is primarily used to facilitate the controlled deposition of solder paste onto a printed circuit board during the assembly process.

- Q: How does using a PCB stencil improve manufacturing efficiency? A: PCB stencils ensure precise solder paste application, reducing setup times, minimizing defects, and enhancing overall production throughput.

- Q: Can I get custom-designed PCB stencils from Pcbasic? A: Pcbasic offers customization options to ensure that the stencil aligns perfectly with your unique design requirements.

- Q: What role does expert guidance play in using PCB stencils effectively? A: Expert guidance from Pcbasic assists manufacturers in optimizing stencil usage, making informed decisions, and achieving the best possible assembly results.

- Q: How do PCB stencils contribute to product quality improvement? A: PCB stencils ensure consistent solder paste deposition, reducing defects like solder bridging and insufficient soldering, thus leading to higher product quality.

With a solid foundation in technology, backed by a BIT degree, Lucas Noah has carved a niche for himself in the world of content creation and digital storytelling. Currently lending his expertise to Creative Outrank LLC and Oceana Express LLC, Lucas has become a... Read more