The Power of Ladder Logic Programming for Automation

In industrial automation, ladder logic programming is a cornerstone of efficiency and precision. Originating from the traditional method of relay logic, this programming language has evolved into a robust tool for controlling manufacturing processes, machinery, and more.

Let’s delve into what ladder logic programming entails, its benefits, and its pivotal role in modern automation systems.

Understanding Ladder Logic Programming

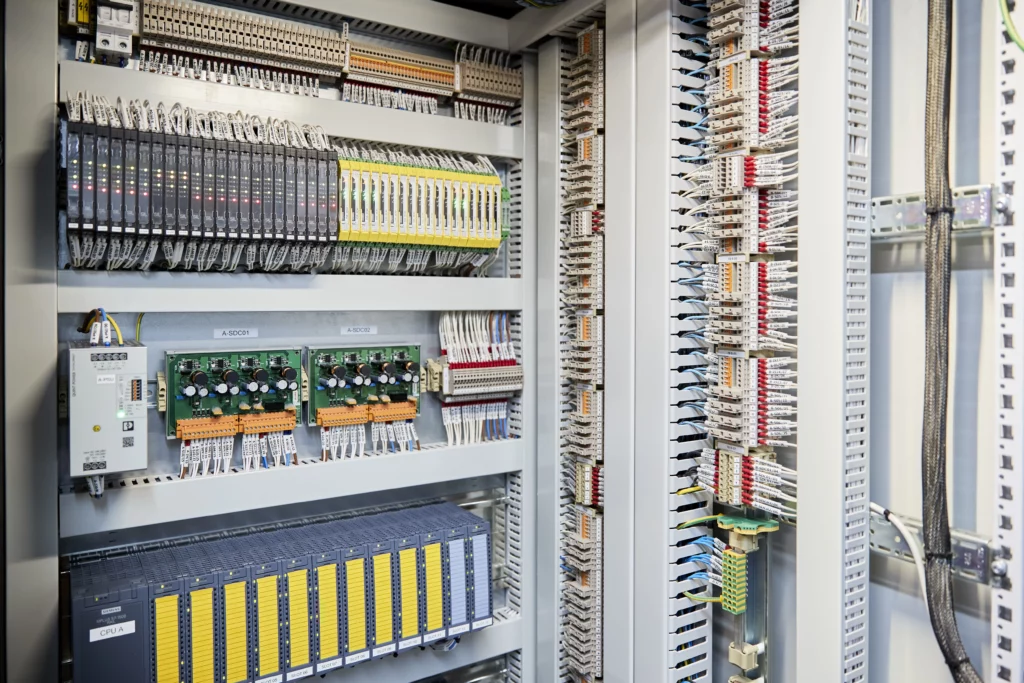

Ladder logic programming is a graphical programming language primarily used in programmable logic controllers (PLCs) to control and monitor industrial processes. It derives its name from its resemblance to a ladder, with rungs representing logical expressions and actions.

Each rung typically consists of input contacts, which act as conditions or triggers, and output coils, which execute actions based on those conditions.

Key Components and Syntax

The fundamental components of ladder logic programming include:

- Contacts: These represent sensors, switches, or other input devices that detect conditions.

- Coils: Actuators or output devices that execute actions based on input conditions.

- Timers and Counters: Manage time-based and count-based operations within the program.

- Relational and Logical Operators: Enable complex decision-making and conditional branching.

- Control and Data Transfer Instructions: Facilitate communication between different parts of the program and external devices.

The syntax of ladder logic programming is intuitive and easy to understand for engineers and technicians familiar with electrical circuits and relay logic. It allows for the creation of sequential logic that mimics traditional relay-based control systems, making it viable for all industrial setups.

Benefits of Ladder Logic Programming

1. Simplicity and Familiarity: Ladder logic programming is based on graphical representation, making it accessible to engineers, technicians, and electricians who are familiar with electrical diagrams and relay logic.

2. Reliability: It is known for its robustness and reliability in controlling industrial processes, ensuring consistent operation without unexpected interruptions.

3. Flexibility: Ladder logic allows for easy modification and troubleshooting of programs, facilitating quick adjustments to accommodate changes in production requirements.

4. Speed and Efficiency: Programs written in ladder logic execute quickly, ensuring rapid response times for controlling machinery and processes.

5. Cost-Effectiveness: Implementing ladder logic programming can lead to cost savings by reducing downtime, minimizing errors, and optimizing operational efficiency.

Applications of Ladder Logic Programming

Ladder logic programming finds application across various industries, including:

- Manufacturing: Controlling assembly lines, robotic systems, and material handling processes.

- Utilities: Monitoring and controlling power distribution, water treatment plants, and HVAC systems.

- Automotive: Managing production lines, quality control processes, and robotic welding systems.

- Food and Beverage: Regulating packaging machines, conveyor systems, and batch processing equipment.

The Future of Ladder Logic Programming

As industries embrace digital transformation initiatives, ladder logic programming continues to evolve. Integration with advanced technologies like Internet of Things (IoT) devices, cloud computing, and machine learning boosts its abilities in real-time data analysis, predictive maintenance, and remote monitoring.

Partnering with Reputable Energy Brands

Partnering with reputable energy brands can provide significant advantages for businesses leveraging ladder logic programming. These partnerships offer access to reliable energy solutions that support sustainable operations, reduce environmental impact, and enhance operational efficiency.

By collaborating with energy experts, businesses can achieve energy savings, optimize resource utilization, and contribute to a cleaner, more sustainable future.

In conclusion, ladder logic programming remains a vital tool in industrial automation, driving efficiency, reliability, and operational excellence across diverse sectors. Its design, coupled with its ability to adapt to evolving technological landscapes, ensures its relevance in changing the future of industrial control systems and internet automation.

Whether you’re exploring the basics of ladder logic programming or seeking to enhance your understanding of its advanced applications, embracing this powerful programming language is key to unlocking new possibilities in automation

With a solid foundation in technology, backed by a BIT degree, Lucas Noah has carved a niche for himself in the world of content creation and digital storytelling. Currently lending his expertise to Creative Outrank LLC and Oceana Express LLC, Lucas has become a... Read more