Reliable and Efficient Manufacturing Process

Vehicle manufacturing involves several stages. From the conception of the design to the final build ready for the buyers, many steps are involved in converting the concepts into an actual vehicle. One of the most critical steps in the fabrication stage of the components involved in the vehicle’s design.

For instance, there will be doors for the vehicle, a body and other crucial parts, which are all critical for the final product. These components need to be highly accurate in terms of their design. They have to be fabricated using a high-precision process that does not cut corners or introduce any inaccuracies into the fabrication.

Vehicles require a design process that will result in a lighter body that is easier to move around without spending a lot of fuel. One of the most lightweight materials that are used in manufacturing is aluminium.

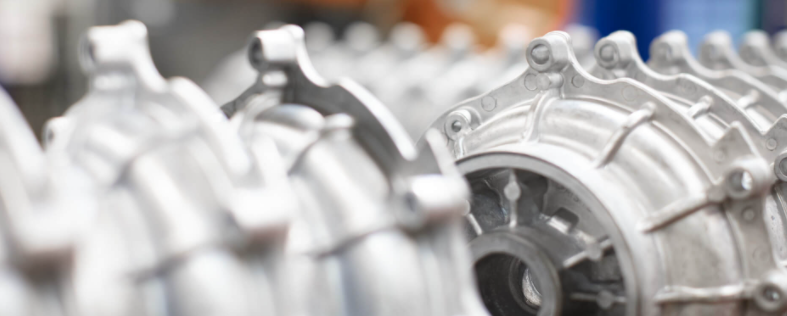

It is strong yet very light, and as such, it can be used to create vehicle parts and components. Aluminum die cast manufacturing uses molten aluminium and a die to create a design according to the engineer’s specifications. This is an essential process in the fabrication and manufacture of new vehicles and has produced outstanding components.

The design starts with the creation of the die itself. The die is used to create an impression on the metal from the inside or outside to create a component of the shape or size that the designer intends.

Once the die is ready, molten aluminium is prepared in a kiln where the required chemicals are added to increase the purity of the final product. This molten product is cast into the die to create the final metal that the engineer has intended to have. This can be anything from vehicle doors to the under-body for modern electric cars.

The benefit of using this process is that the components can be mass-produced at a lower price which increases efficiency and adds to the economic profitability of the entire approach. Any vehicle manufacturer that uses aluminium die cast manufacturing, see more here https://www.ekoindustries.com/precision-die-casting/aluminium-die-casting/, for their vehicle components can significantly reduce the production cost for each unit, and they can also produce more units per cycle. The accuracy of the manufacturing process is also increased, which adds to the overall efficiency of the vehicle manufacturer.

The process is also economically more feasible for manufacturing industries with vast amounts of the same product to deliver to their customer in less time. Whenever they can create accurate designs at a tremendous rate with aluminium die cast manufacturing, they will be able to cater to the needs of their customers and ensure that they deliver on time.

The timely manufacturing of the components also means that the companies will provide what their customers need and profit by doing so. This is important for the modern economy where customers always want timely services and an exceptional level of quality on all the products they purchase.

For happier customers who genuinely appreciate your final product, you can use die casting for more accurate designs that they will love.

With a solid foundation in technology, backed by a BIT degree, Lucas Noah has carved a niche for himself in the world of content creation and digital storytelling. Currently lending his expertise to Creative Outrank LLC and Oceana Express LLC, Lucas has become a... Read more