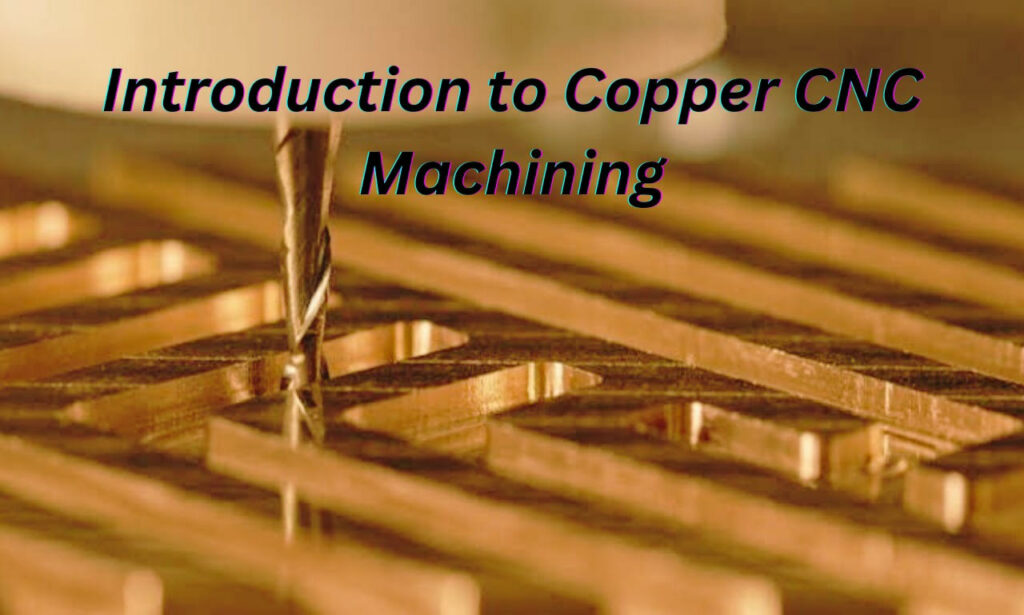

Introduction to Copper CNC Machining

In the world of modern manufacturing, precision is paramount. Industries demand high-quality components that can withstand various conditions while maintaining their structural integrity. One material that has gained significant attention in this regard is copper. Copper CNC machining is a process that combines the exceptional properties of copper with the precision of Computer Numerical Control (CNC) technology. This article delves into the world of copper CNC machining, exploring its benefits, applications, and the future it holds in the manufacturing landscape.

Understanding the Basics of CNC Machining

Before delving into copper CNC machining, it’s crucial to understand the fundamental concept of CNC machining. CNC machining is a subtractive manufacturing process where a computer-controlled machine precisely removes material from a workpiece to create a final product. This technology enables the production of intricate and complex parts with incredible accuracy.

The Advantages of Using Copper in CNC Machining

Copper is a highly conductive and corrosion-resistant metal, making it an ideal choice for a wide range of applications. Its advantages in CNC machining include exceptional thermal and electrical conductivity, malleability, and the ability to produce fine details. Copper components are used in industries like electronics, aerospace, and telecommunications.

Types of Copper Alloys for CNC Machining

Copper alloys offer varying properties for specific applications. Common alloys used in CNC machining include brass, bronze, and copper-nickel. Each alloy has unique characteristics that cater to different requirements, ensuring versatility in CNC machining projects.

CNC Machining Processes for Copper

CNC machining processes for copper encompass turning, milling, and drilling. These processes provide manufacturers with the flexibility to create components of different shapes and sizes. The choice of the machining process depends on the complexity of the part and the desired end result.

Precision and Tolerances in Copper CNC Machining

Achieving high precision and tight tolerances is one of the primary goals in CNC machining. Copper’s malleability and the precision of CNC machines allow manufacturers to produce intricate parts with exacting specifications, meeting the demands of various industries.

Applications of Copper CNC Machining

Copper CNC machining finds applications in a multitude of industries. From manufacturing intricate components for electronics to creating robust parts for the aerospace sector, the versatility of copper cnc machining is virtually limitless.

Choosing the Right CNC Machine for Copper

Selecting the appropriate CNC machine is crucial for the success of copper CNC machining. Different machines are designed for specific tasks, and understanding the machine’s capabilities ensures optimal results.

Tips for Successful Copper CNC Machining

Success in copper CNC machining depends on several factors, including tool selection, cutting speeds, and feeds. This section provides valuable tips for achieving exceptional results in copper CNC machining projects.

Ensuring Quality and Efficiency in Copper CNC Machining

Quality control and efficiency are vital in any manufacturing process. Here, we explore the methods and techniques to ensure that copper CNC machining projects meet the highest standards of quality and efficiency.

The Future of Copper CNC Machining

The future of copper CNC machining is promising, with ongoing advancements in technology and materials. This section discusses the emerging trends and innovations that will shape the industry.

Case Studies: Real-World Applications

Real-world examples of copper CNC machining applications showcase the versatility and impact of this technology across different industries.

Cost Considerations in Copper CNC Machining

While copper CNC machining offers numerous advantages, it’s essential to consider the cost factors involved in the process. This section highlights cost considerations that manufacturers need to be aware of.

Environmental Impact and Sustainability

Sustainability is a growing concern in the manufacturing industry. We explore the environmental impact of copper CNC machining and the steps being taken to ensure a more sustainable future.

Conclusion: Embracing Copper CNC Machining for the Future

In conclusion, copper CNC machining offers a wealth of benefits and applications, making it a valuable resource in modern manufacturing. As industries continue to evolve, embracing this technology will undoubtedly lead to innovative solutions and advancements. Copper CNC machining has a bright future as it plays a pivotal role in creating the components that power our world.

FAQs

1. Is copper a good material for CNC machining?

- Yes, copper is an excellent material for CNC machining due to its high conductivity and malleability, making it suitable for a wide range of applications.

2. What are the primary industries that benefit from copper CNC machining?

- Copper CNC machining is commonly used in electronics, aerospace, telecommunications, and more.

3. How does copper CNC machining contribute to sustainability?

- Copper is a recyclable material, and the precision of CNC machining reduces waste, making it a sustainable choice.

4. What are the cost considerations in copper CNC machining?

- Cost factors include material cost, machine setup, and tooling expenses.

5. What is the future of copper CNC machining?

- The future looks promising, with ongoing technological advancements and an increasing demand for precision components in various industries.